Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

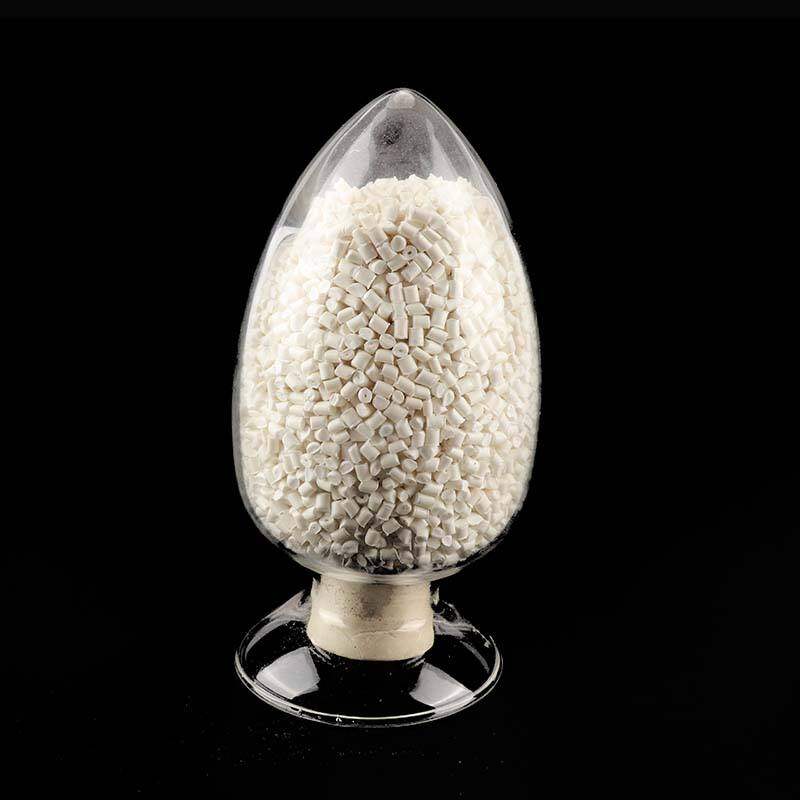

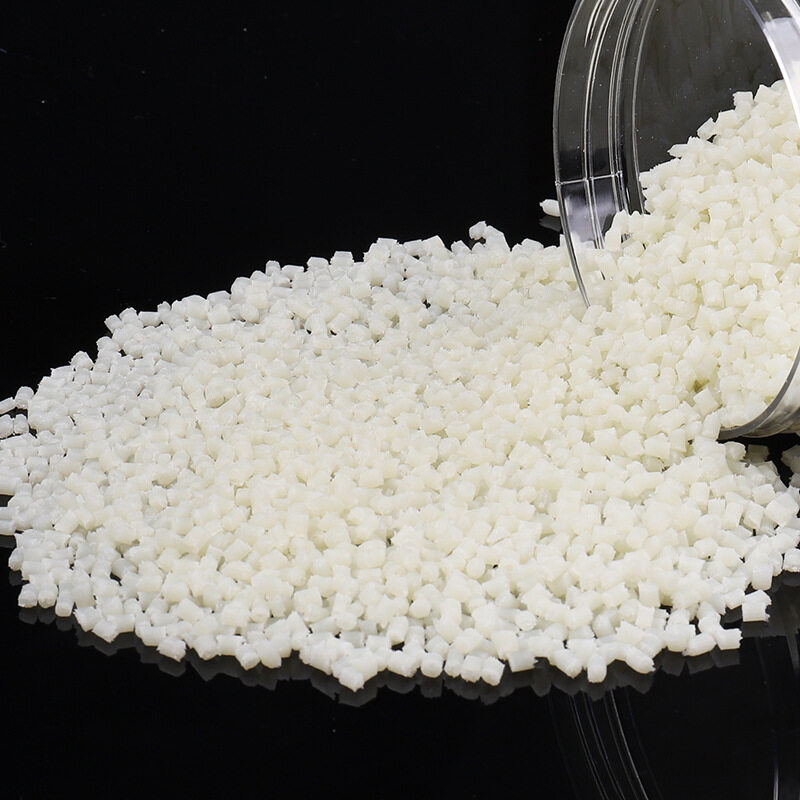

PA66 GF35 F0735

Glass Filled: 35%

(Custom materials available according to your Technical Data Sheet)

- Product Details

-

Download

Customizable Materials Available:

- Color (Customization of plastic pellet color according to your requirements.)

- Flame retardant grade (Let us know which flame retardant level you need: 0.8mm-3.0mm HB, V0, V1, V2, 5VA, 5VB)

- Glass fiber reinforcement material (10%-50% availability)

- Carbon fiber reinforcement material (10%-50% availability)

- UV resistance property (Tell us the application scenarios or UV resistance level of the materials.)

- Other materials can also be customized (Just need to provide your Technical Data Sheet.)

Technical Data Sheet of PA66 GF35 F0735

| 拓扑新材料 名称: PA66GF35 TOPONEW 牌号: F0735 |

||||

| 产品简介 Product Description | 主要应用 Applications | |||

| ·35%玻纤增强尼龙66 35% glass fiber reinforced PA66 | ·注塑成型 Injection molding | |||

| ·优异的耐热性能 Excellent heat stability | ·良好的机械性能 Good mechanical properties balance | |||

| 性能 Properties |

测试标准 Test Method |

测试条件 Test Condition |

单位 Unit |

典型值 Typical Values |

| 物理性能 Physical properties | ||||

| 密度 Specific Gravity | ISO 1183 | 23℃ | g/cm3 | 1.4 |

| 灰份Ash | ISO 3451 | 800℃,30min | % | 35 |

| 机械性能 Mechanical properties | ||||

| 拉伸强度Tensile Strength | ISO 527 | 50mm/min | MPa | 215 |

| 弯曲模量 Flexural Modulus | ISO 178 | 2mm/min | MPa | 10848 |

| 弯曲强度 Flexural Strength | ISO 178 | 2mm/min | MPa | 347 |

| 简支梁缺口冲击强度 Charpy Notched Impact Strength |

ISO 179-1eA | 23℃ | kJ/㎡ | 14 |

| 简支梁无缺口冲击强度 Charpy Unotched Impact Strength |

ISO 179-1eU | 23℃ | kJ/㎡ | 97 |

| 热性能 Thermal properties | ||||

| 热变形温度 Heat deflection temperature |

ISO 75 | 1.80MPa | ℃ | 235 |

| 熔点 Melting Point | DSC | - | ℃ | 260 |

| 其它性能 Other properties | ||||

| 阻燃性 Flammability | UL94 | - | HB | |

| 说明:以上数据是典型值,不是保证值。根据模具设计,例如浇口类型,浇口分布,浇口数量的不同,注塑工艺和制件厚 度的不同,测试结果会有波动。不同的颜色,测试结果也会有波动。在使用材料之前,请咨询苏州拓扑新材料有限公司。 Note:The data above is typical value for reference, not guarantee value. The data will vary with tool design such as gate type,gate location, gate number, injection molding process and part thickness. The data will vary with different color as well. Prior to use the material, please consult with TOPONEW. |

||||

Welcome to the detailed introduction page of TOPONEW PA66 GF35, a high-performance plastic granule. With its exceptional physical and mechanical properties, this product is designed to meet the diverse requirements of various industrial applications. Let's delve into the specific attributes that make TOPONEW PA66 GF35 a preferred choice for discerning professionals.

Properties of PA66 GF35

Physical Properties of PA66 GF35

-

Specific Gravity (Density): With a value of 1.4 g/cm3 at 23℃, the TOPONEW PA66 GF35 showcases a balanced weight-to-volume ratio, enabling lightweight yet sturdy components.

-

Ash Content: Tested at 800℃ for 30 minutes, this material exhibits an ash content of 35%. This attribute speaks to its composition and purity, ensuring reliable performance and stability.

Mechanical Properties of PA66 GF35

-

Tensile Strength: Compliant with ISO 527 standards, the TOPONEW PA66 GF35 provides a remarkable tensile strength of 215 MPa when the test is conducted at a rate of 50mm per minute. This strength ensures durability and structural integrity in demanding applications.

-

Flexural Modulus: Measured at 2mm per minute according to ISO 178, this material displays an impressive flexural modulus of 10848 MPa. This attribute highlights its resistance to bending and ability to maintain shape under load.

-

Flexural Strength: The TOPONEW PA66 GF35 exhibits a flexural strength of 347 MPa when tested under ISO 178 standards at a rate of 2mm per minute. This characteristic translates to high resistance against deformation, enabling reliable performance in various structural applications.

-

Charpy Notched Impact Strength: As per ISO 179-1eA guidelines and at a temperature of 23℃, this material exhibits a Charpy notched impact strength of 14 kJ/m2. This property indicates its ability to withstand sudden impacts and absorb energy efficiently, ensuring enhanced safety.

-

Charpy Unnotched Impact Strength: Similarly tested under ISO 179-1eU standards at 23℃, the TOPONEW PA66 GF35 showcases a Charpy unnotched impact strength of 97 kJ/m2. This feature underscores its resilience against impacts in demanding environments.

Thermal Properties of PA66 GF35

-

Heat Deflection Temperature: With a heat deflection temperature of 235℃ at 1.80 MPa, determined according to ISO 75 standards, the TOPONEW PA66 GF35 exhibits excellent resistance to deformation under elevated temperatures, ensuring stability in demanding thermal conditions.

-

Melting Point: Determined through DSC analysis, this material has a melting point of 260℃, further highlighting its exceptional heat resistance.

Other Properties:

- Flammability: The TOPONEW PA66 GF35 possesses a UL94 flammability rating of HB, implying that it exhibits self-extinguishing properties and resists sustained combustion. This attribute enhances safety and diminishes the risk of fire hazards.

TOPONEW PA66 GF35 is a high-quality plastic granule that offers a powerful combination of physical, mechanical, thermal, and flammability properties, making it an excellent choice for a wide range of applications in the injection molding polyamide 66 market. Whether you're involved in automotive, electrical, or industrial manufacturing, this product empowers you to achieve reliable and efficient results. Experience the difference that TOPONEW PA66 GF35 can make in your projects today.

What is PA66 GF material?

PA66 GF material refers to a type of material made from PA66 (Nylon 66) resin reinforced with glass fiber (GF). PA66 is a type of polyamide engineering thermoplastic known for its high strength, toughness, and excellent mechanical properties.

The addition of glass fibers to PA66 resin enhances its mechanical properties, making it even stronger, stiffer, and more rigid. The glass fibers also improve the dimensional stability, heat resistance, and wear resistance of the material.

PA66 GF material is commonly used in various industries for applications that require high strength, stiffness, and impact resistance. It is widely used in automotive components, electrical and electronic parts, industrial components, and consumer goods where durability and performance under harsh conditions are essential. The specific ratio of glass fibers in PA66 GF material can vary depending on the intended application and desired properties of the final product.

Download

-

PA66GF35 F0735.pdf

Download PA66GF35 F0735.pdf